Palm Oil Automation Retrofit

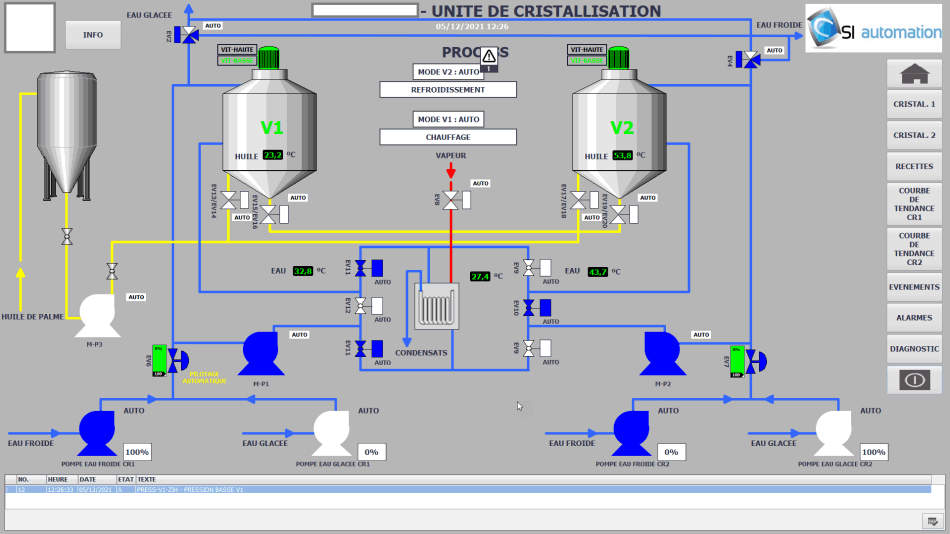

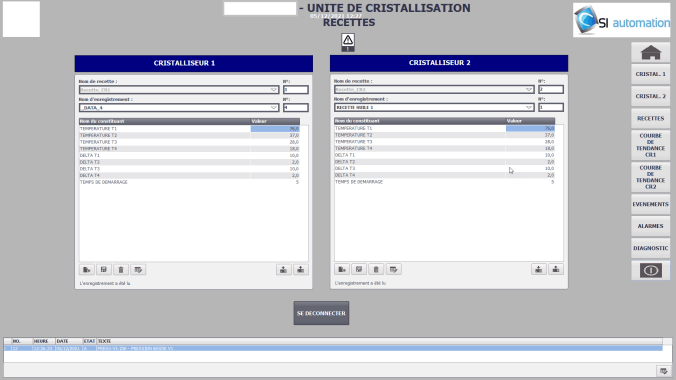

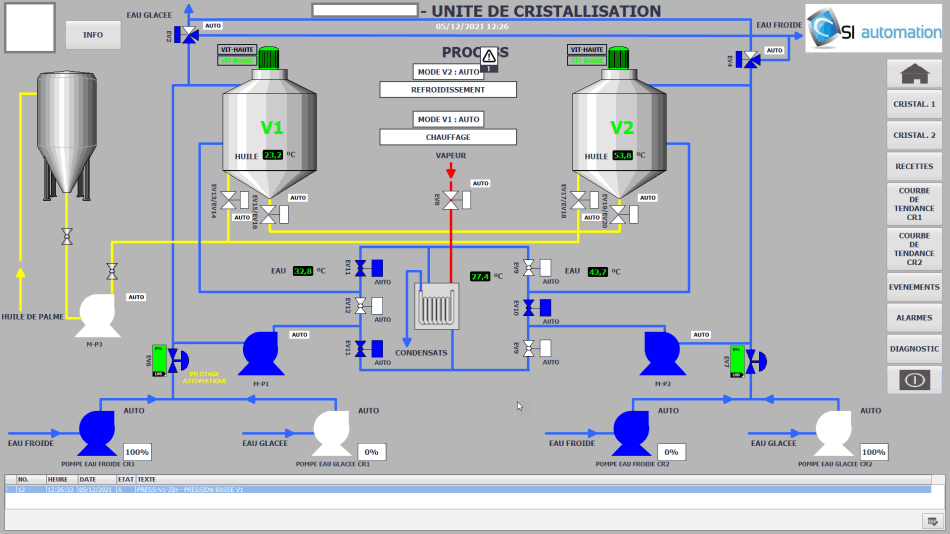

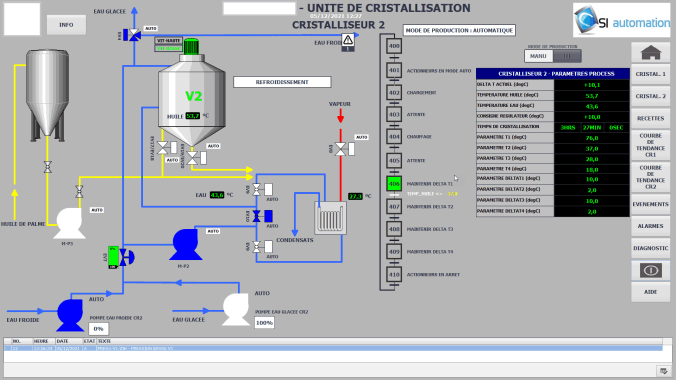

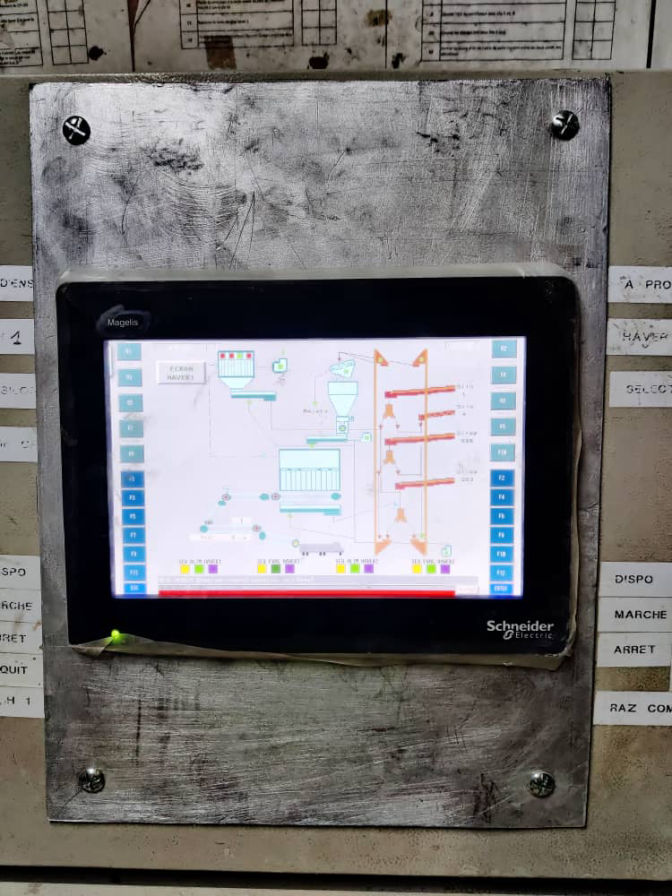

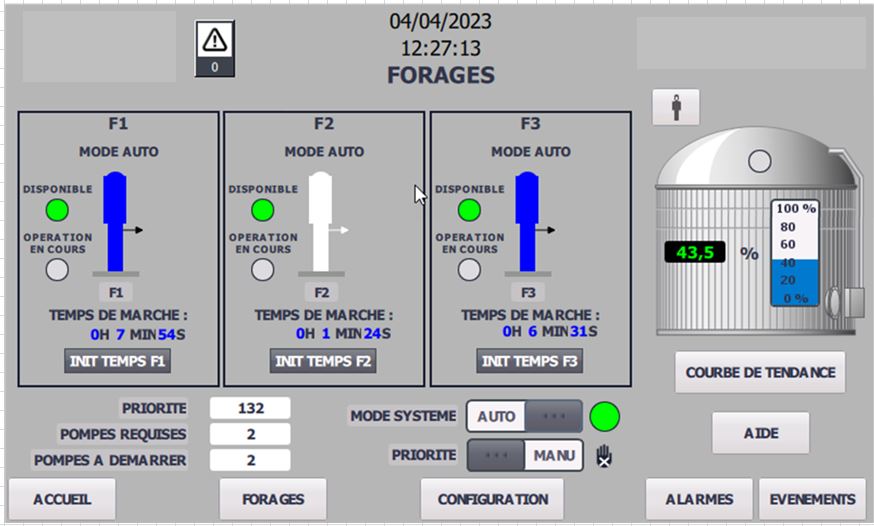

The Challenge: Replace a locked, obsolete system (Siemens S7-300 & custom serial SCADA) with no source code and password-protected access. The Solution: - Reverse Engineering: Full reconstruction of the logic using wiring diagrams and screenshots. - Collaboration: Series of workshops to validate the Functional Analysis. - HMI Upgrade: Development of a modern interface with Recipe Management. - Performance: Optimization of PID regulation loops. - The Result: Operators are fully trained, and the process control is now stable and efficient

- Detailed Engineering: Control System Cabinet Drawings, I/O lists, Functional Analysis, Network Diagrams

- PLC: Siemens S7-300

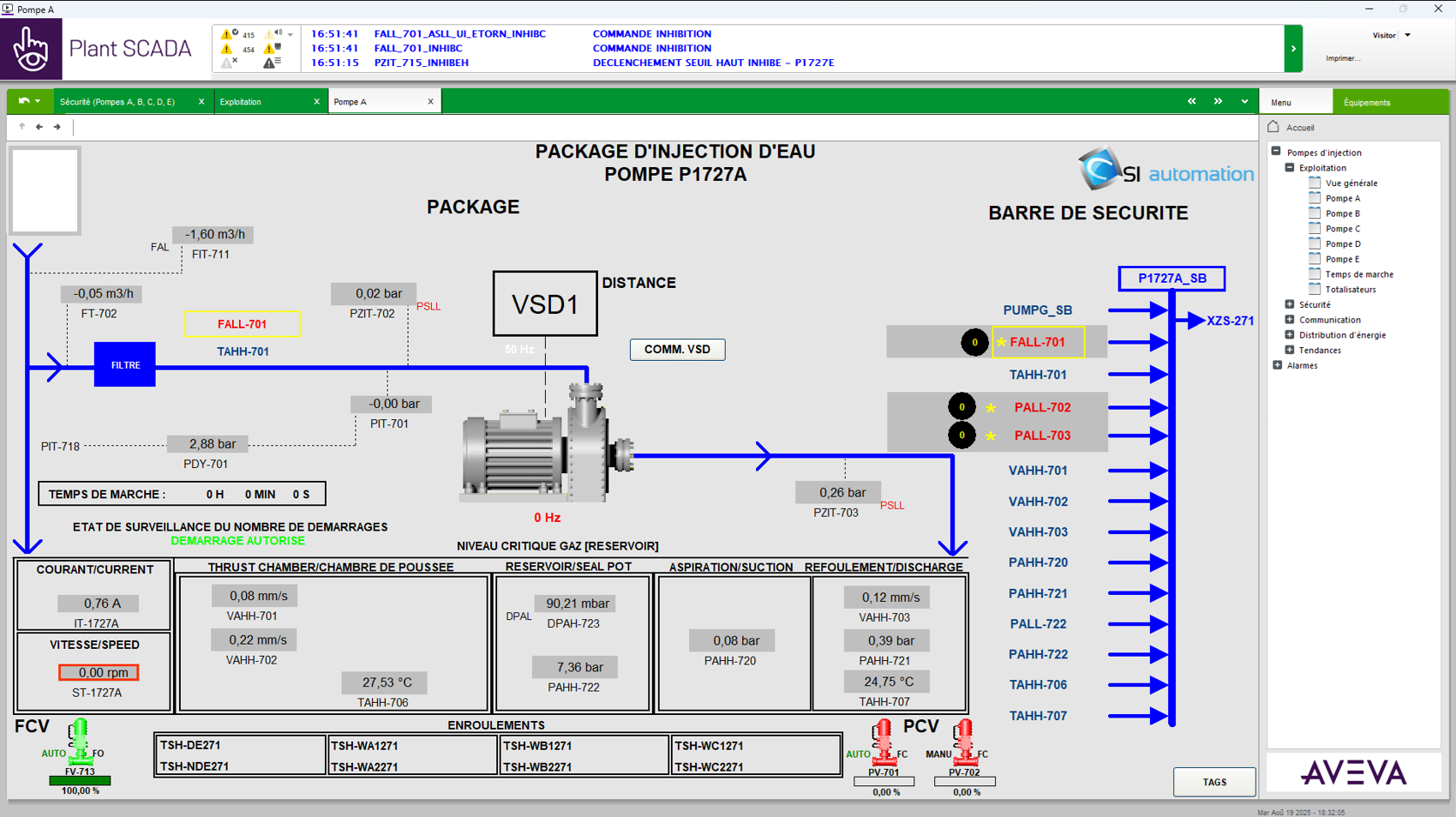

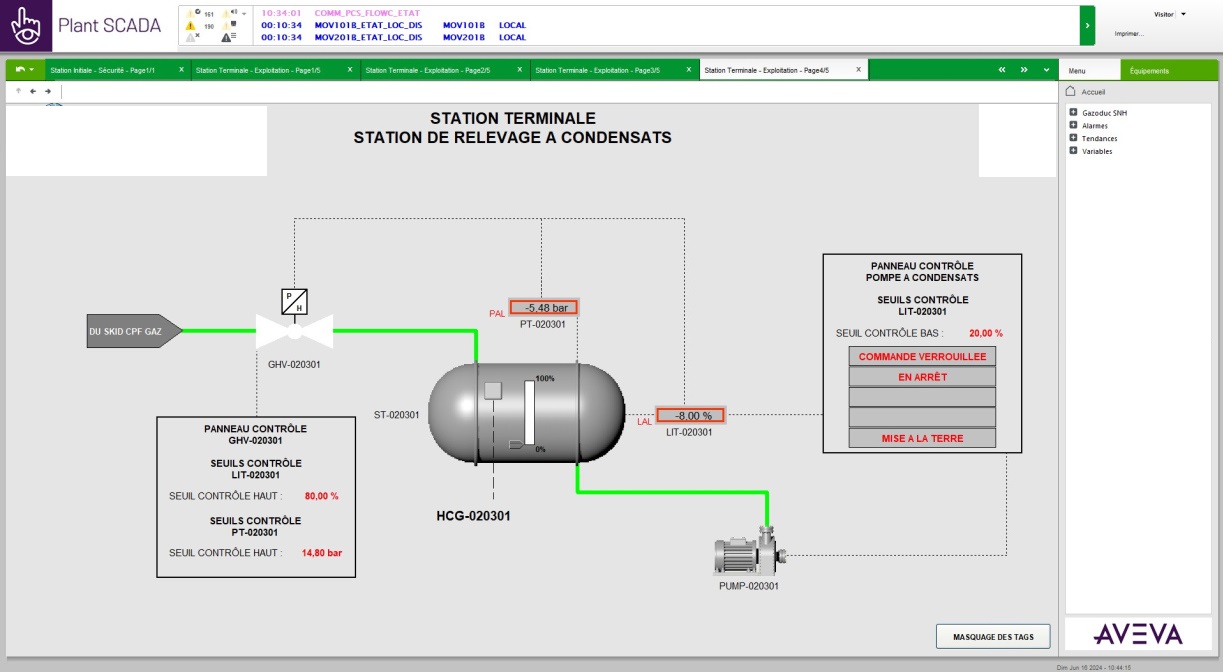

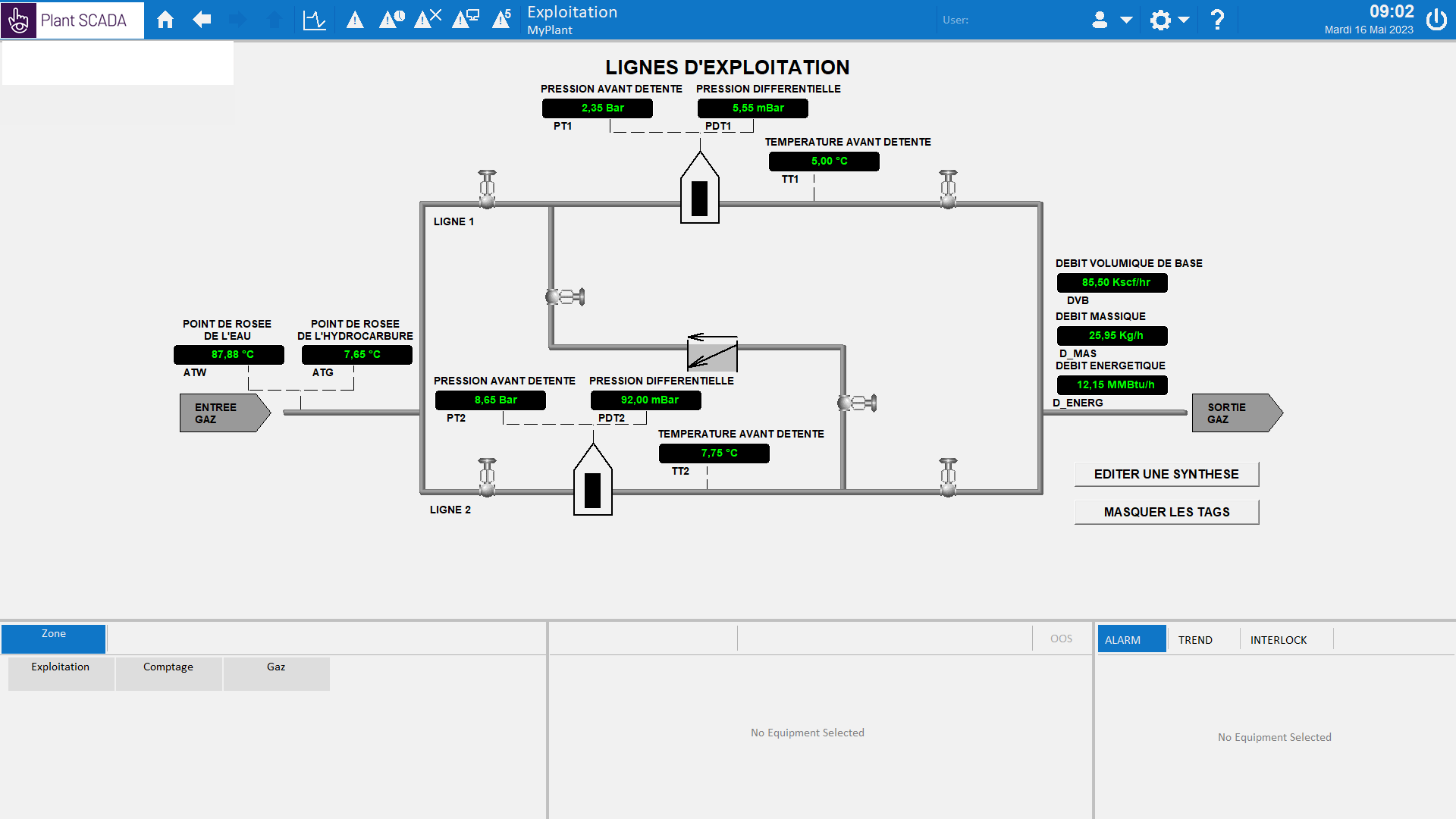

- HMI SCADA: WinCC Advance Runtime V15