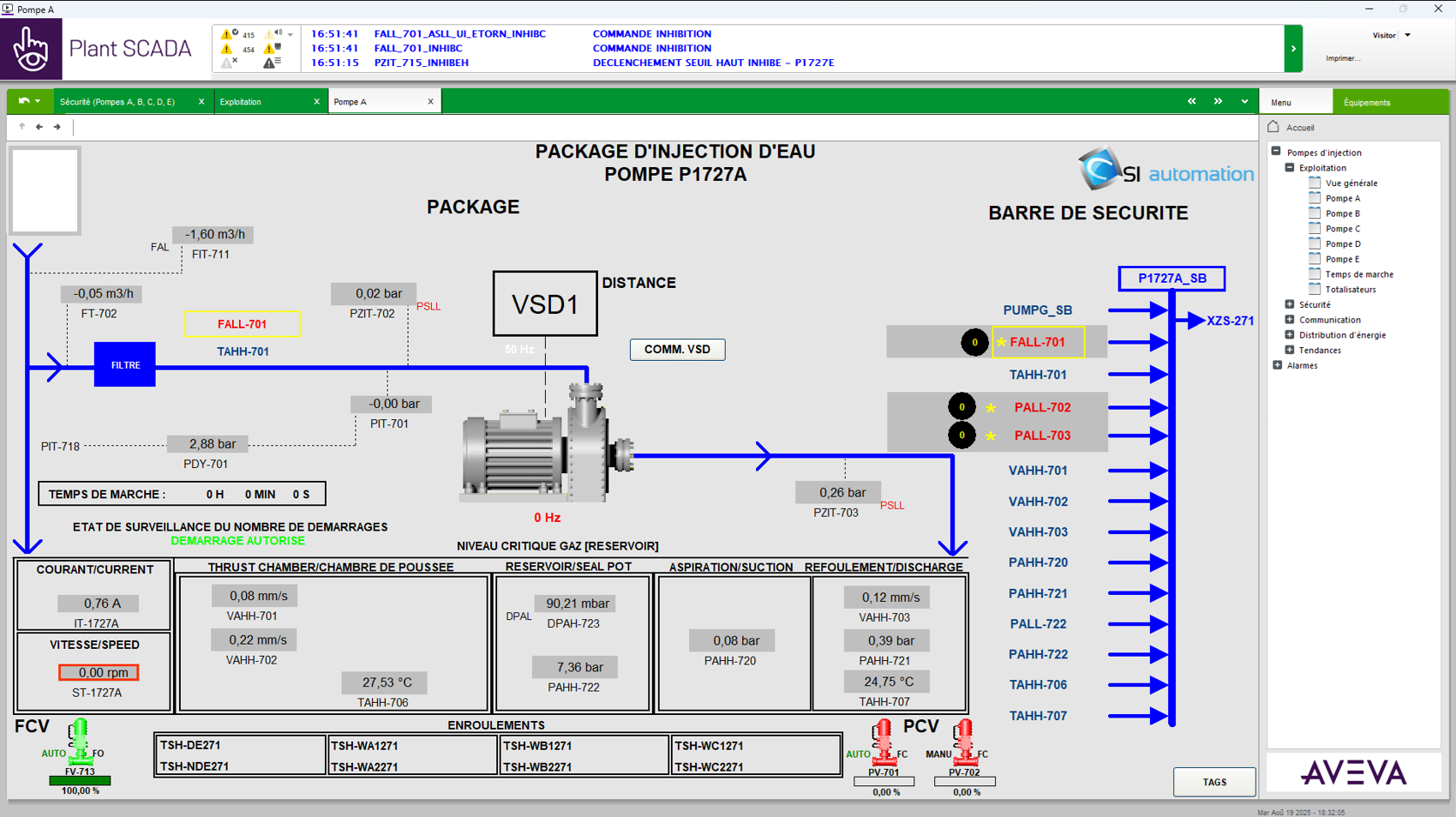

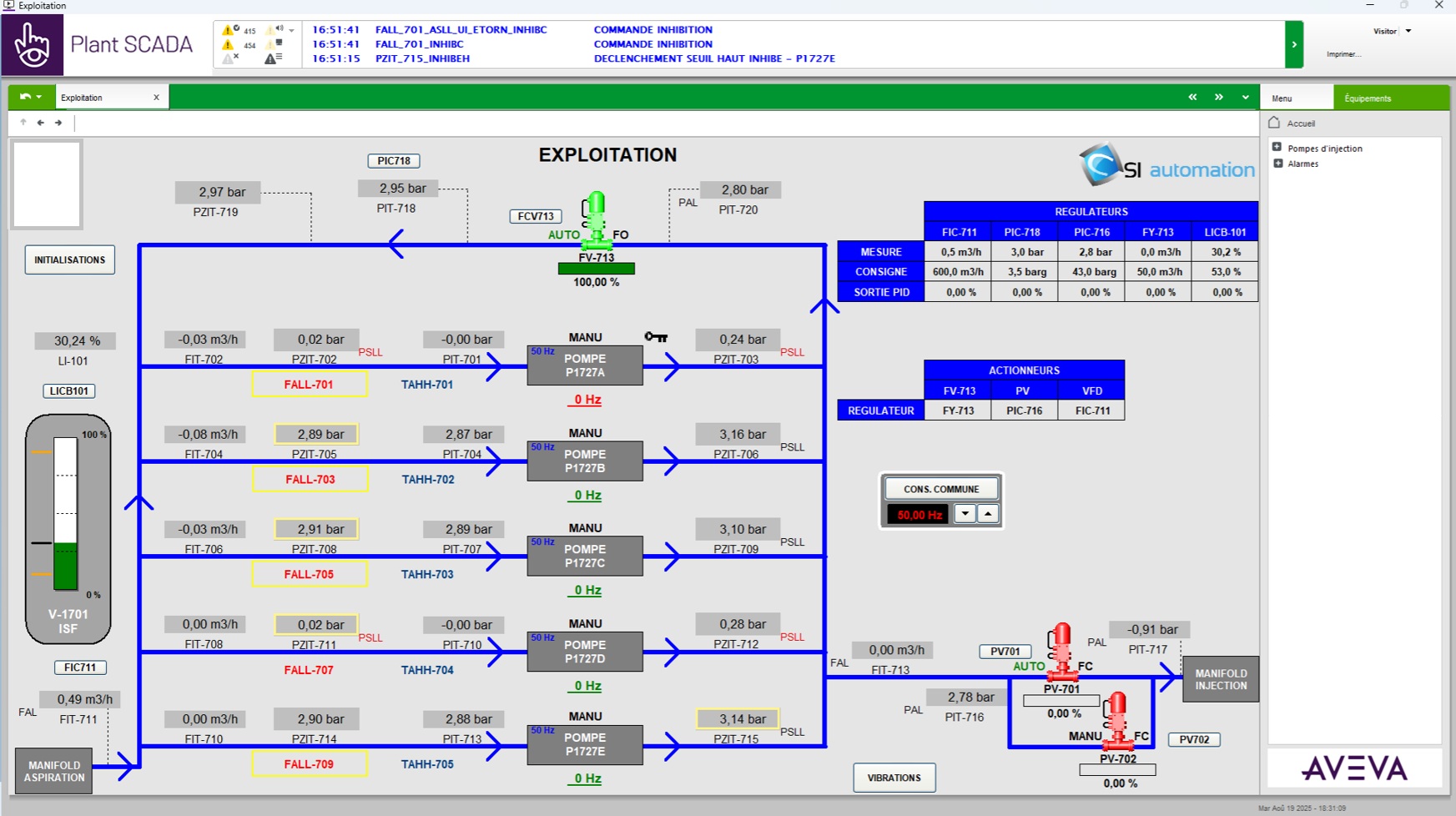

ICSS For Water Injection Process Unit

Complete scope managed through rigorous project management, ensuring delivery on time and within budget while providing a technically advanced solution.

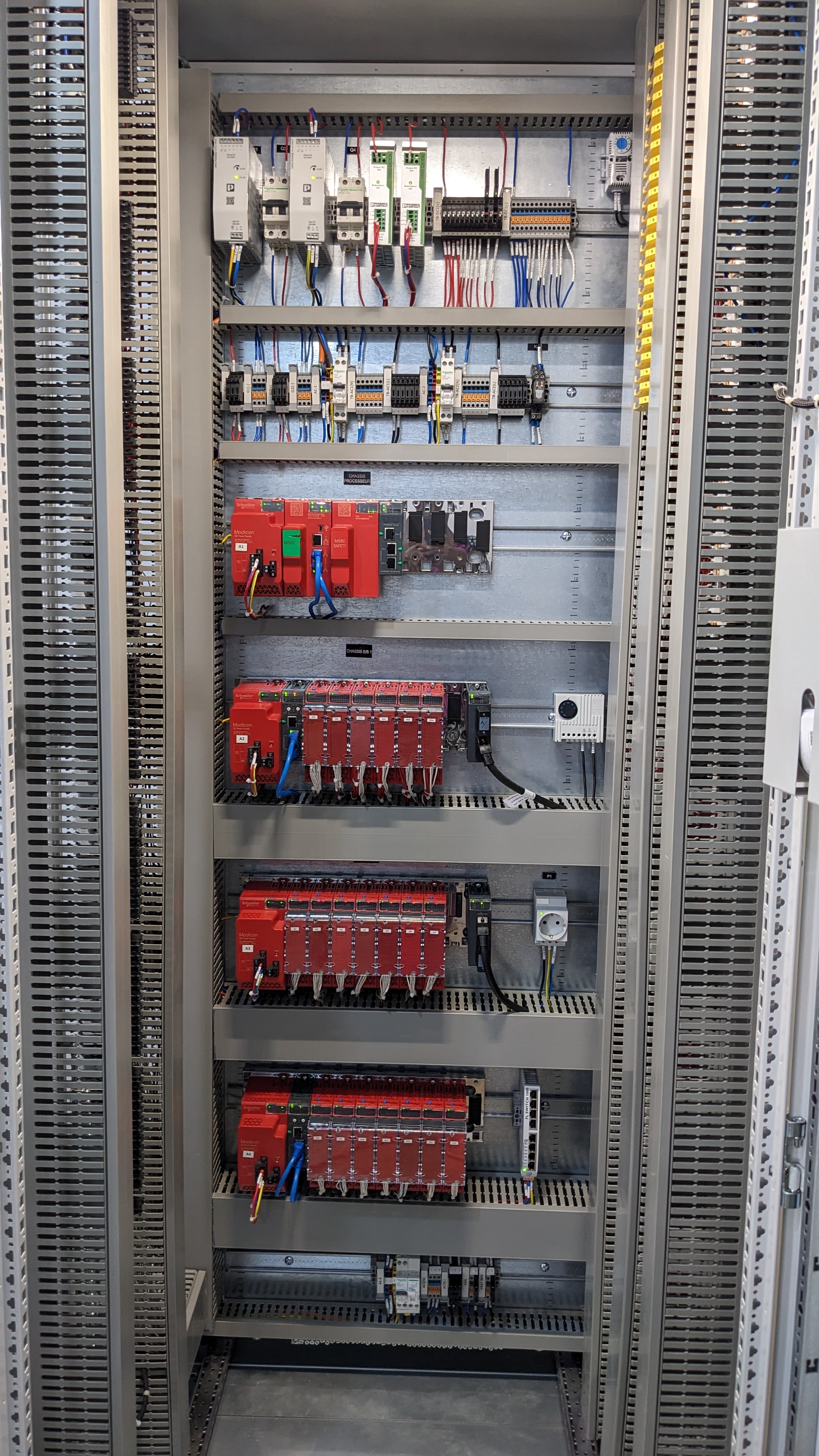

- Detailed Engineering: Cabinet Drawings, I/O lists, System Architecture, Loop drawings, Cabinet Wiring Diagrams

- Procurement: PLC Modules, CPU, I/Os, Communication Module, Power Supplies, Cabinet

- Process PLC: M580

- Safety PLC: M580 Safety

- HMI SCADA: Aveva Plant Scada 2023 R2