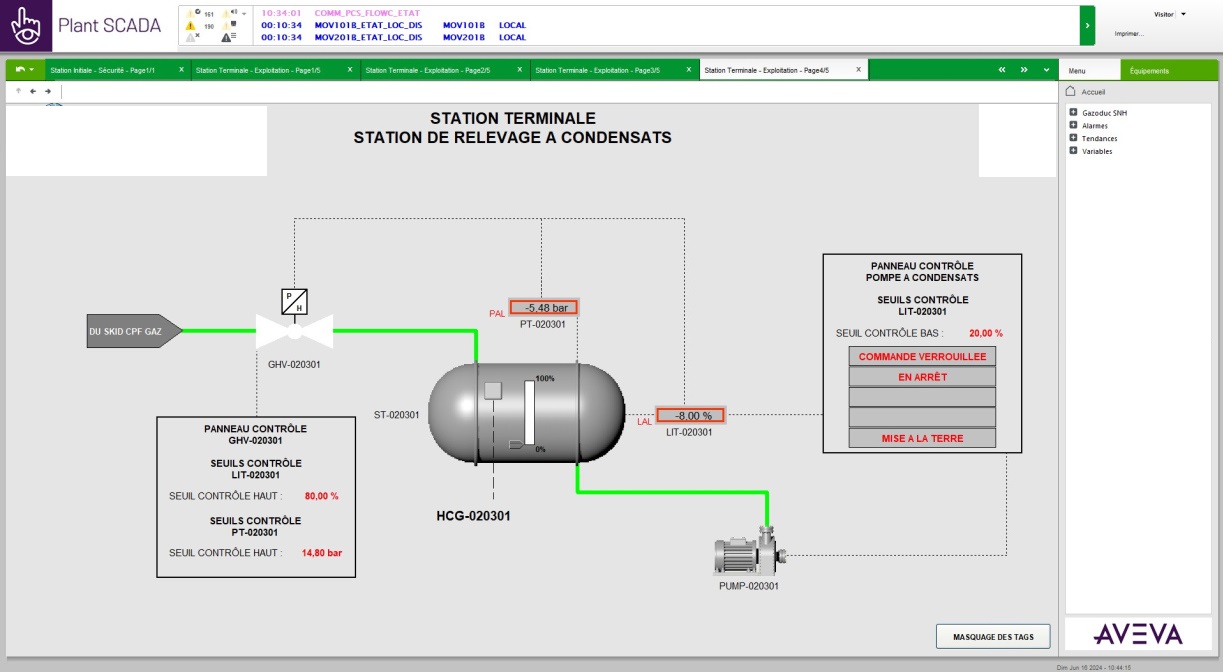

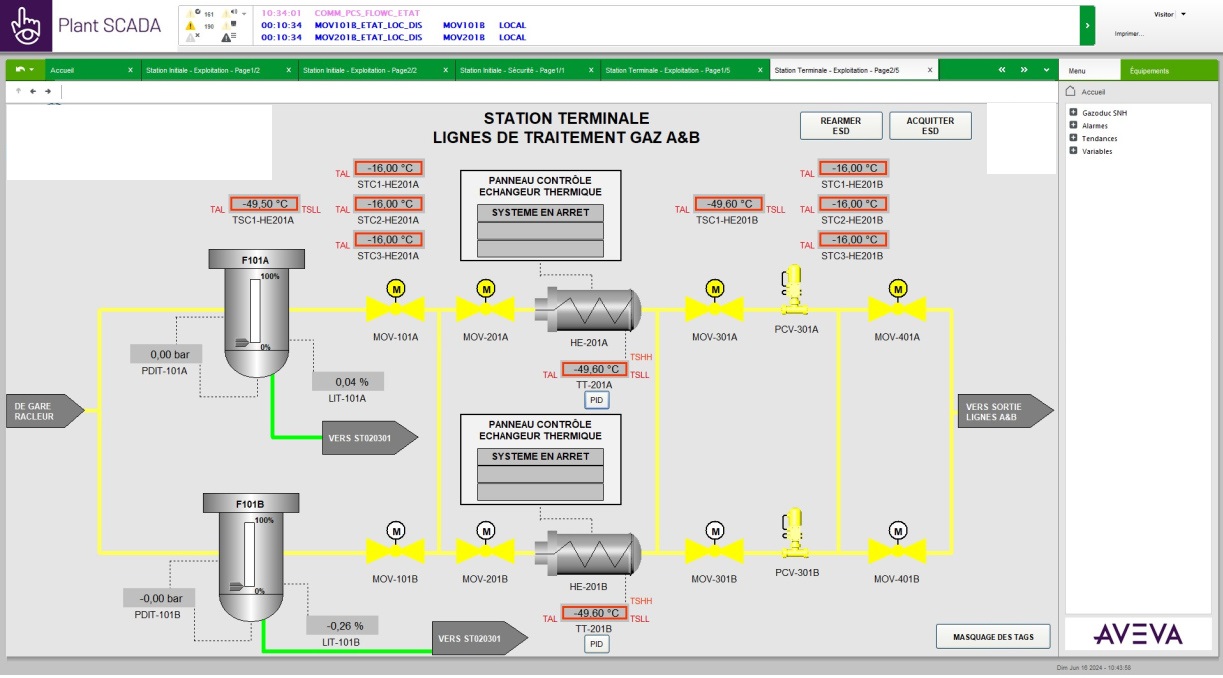

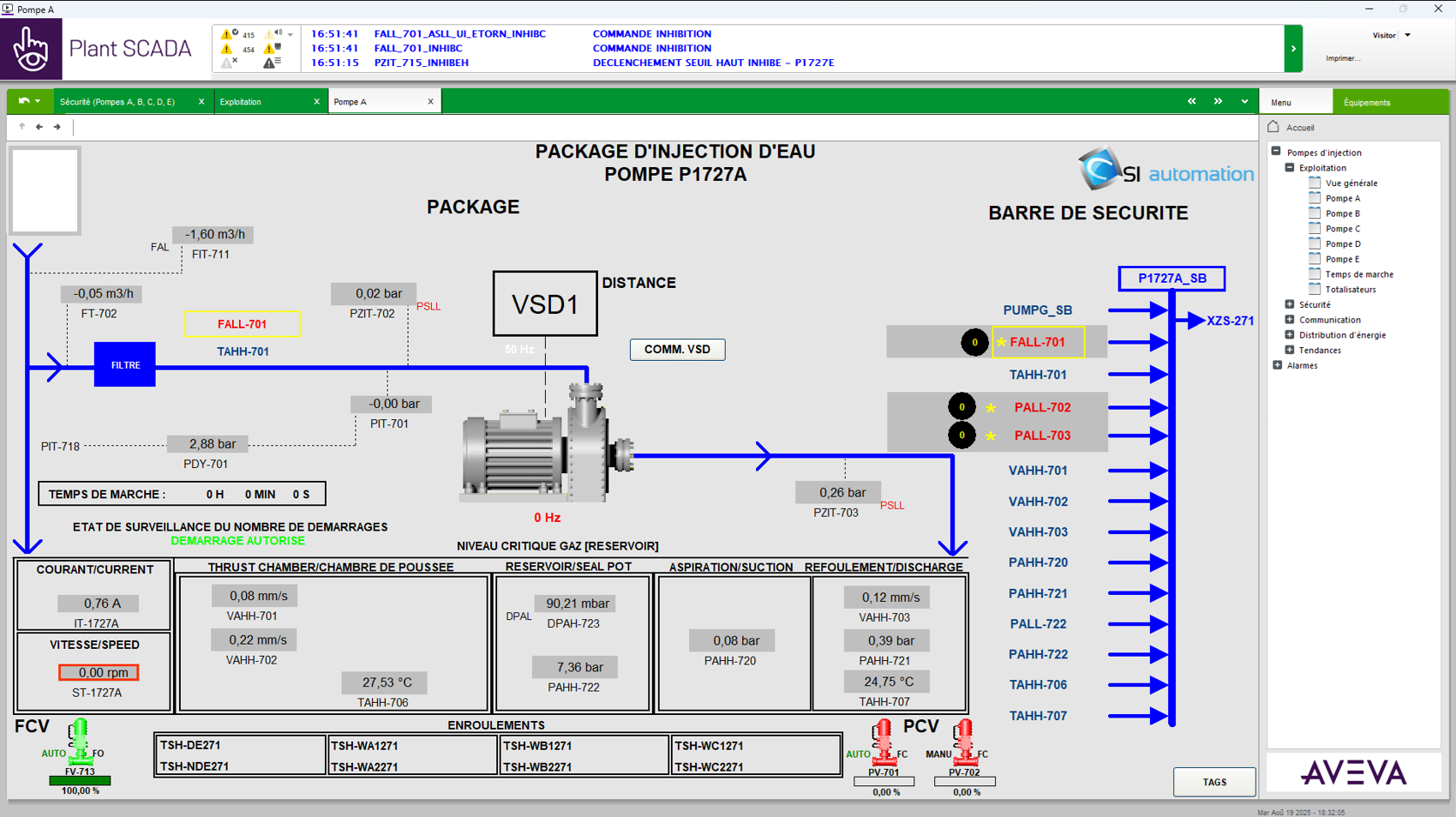

ICSS for a gas pipeline

A highly complex technical project featuring advanced communication with third-party packages (via Modbus TCP and RS485). The scope integrates Process Control, Safety Automation, and Supervision (SCADA).

- Detailed Engineering: Cabinet Drawings, I/O lists, System Architecture, Loop drawings, Cabinet Wiring Diagrams

- Process PLC: M580

- Safety PLC: M580 Safety

- HMI Scada: Aveva Plant Scada 2023 R2